Coated Powders

Enabling the future of material design

Customized solutions

Our coated powders are used in a wide variety of areas.

Additive manufacturing (AM)

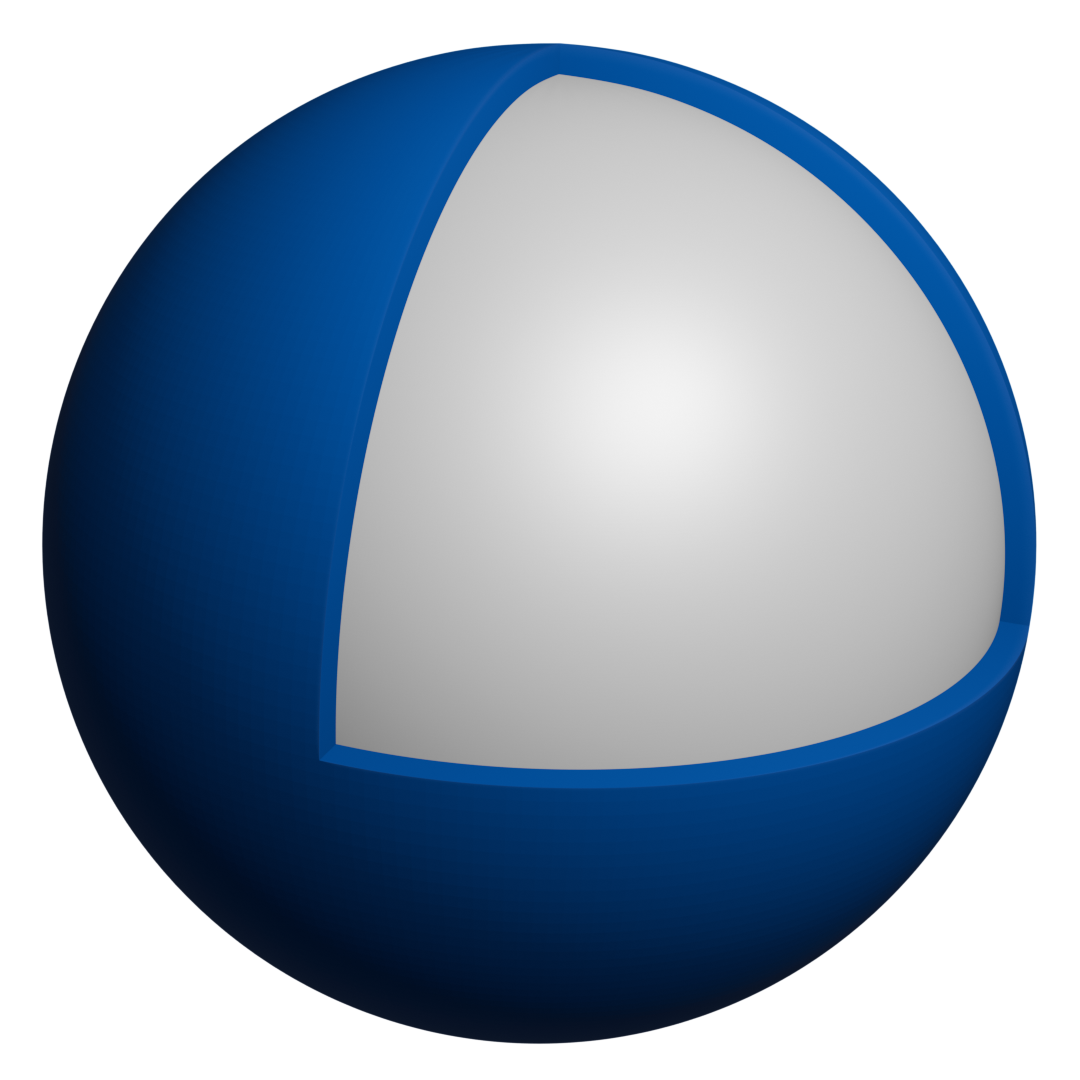

Unique core-shell powders for AM applications

Nanostructured material design

Customized materials for high-tech applications

Catalysts

Reduced use of precious metals by applying to a low-cost carrier powder

Recycling valuable raw materials

Support for recycling magnetic powders by reprocessing the surface

Technology

Our technology enables the production of unique, customized core-shell structures. The powders (core) used can be selected as desired and the coating (shell) architecture can be freely designed. Due to the low temperatures during coating with the patented technology, there are no restrictions on powders and coatings.

Are you interested in or have questions about Core-Shell powder?

Beyond powder

Our process chain has a modular structure – allowing services to be purchased on an as-needed basis along individual process steps.

Acquisition of powder

Through our network of established suppliers, we ensure the availability of high-quality, application-specific powders.

Applying the shell

Coating takes place at the university’s R&D site, which features state-of-the-art infrastructure, a well-defined production environment, secure process control, and high reproducibility.

Production of the material

Together with a broad network of partners, we carry out further processing into functional materials—from laboratory scale to small series production.

Shipping

Prototypes are delivered by the shortest possible route – efficiently, flexibly, and tailored to the needs of research and industry.

Who are we?

Jürgen Bauer

CEO, Co-Founder

David Böhm

CTO, Co-Founder

We are a young, dynamic, and agile team with a passion for technological innovation. With over 20 years of combined experience in thin-film technology and PVD coating of powders, we combine scientific depth with industrial practice.

Our strong network of partners, cooperation projects, and institutions forms the basis for innovative and flexible development of novel materials along the entire value chain.

News

-

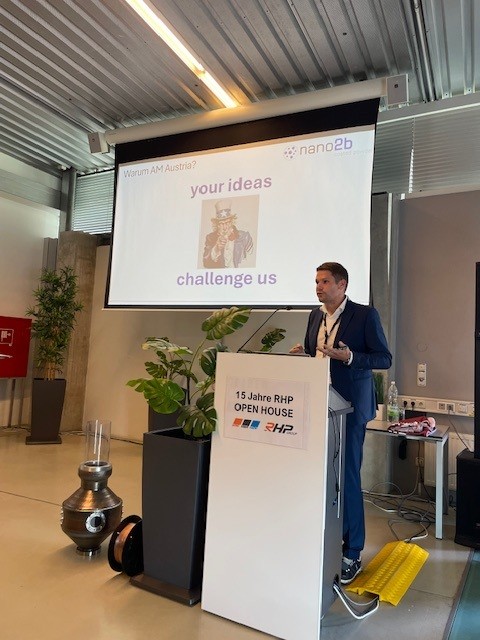

AM Austria General Meeting 2025

Read more: AM Austria General Meeting 2025nano2b presents innovative coated powder at the Additive Manufacturing Austria general meeting On October 2, the time had come: at […]

-

SCHWEISSEN & SCHNEIDEN 2025

Read more: SCHWEISSEN & SCHNEIDEN 2025nano2b at the SCHWEISSEN & SCHNEIDEN 2025 trade fair – Coated powders as the key to modern build-up welding and […]

-

Copper AM for Industry

Read more: Copper AM for Industrynano2b at CopperAM for Industry – New impulses for coated copper powders in additive manufacturing When it comes to demanding […]

Are you interested in or have questions about Core-Shell powder?